Get a Refined and Classy Look with Tint Pros Vinyl Wraps Solutions

Get a Refined and Classy Look with Tint Pros Vinyl Wraps Solutions

Blog Article

The Ultimate Guide to Picking the Right Vinyl Covers for Your Job

Choosing the proper plastic cover for your job needs a nuanced understanding of numerous variables that affect both aesthetic appeals and performance. As you navigate these factors to consider, it becomes clear that the path to an effective plastic cover task is layered with essential decisions that merit more expedition.

Sorts Of Plastic Covers

When picking plastic wraps, comprehending the numerous kinds available is important. Vinyl covers can be broadly categorized into two major types: cast vinyl and calendared plastic.

On the other hand, calendared plastic is produced by a procedure that entails rolling and extending vinyl sheets. This kind is usually thicker and cheaper than cast vinyl, making it appropriate for flat surface areas and short-term applications. While calendared vinyl provides an affordable option, it may not execute too on elaborate layouts or in severe weather conditions.

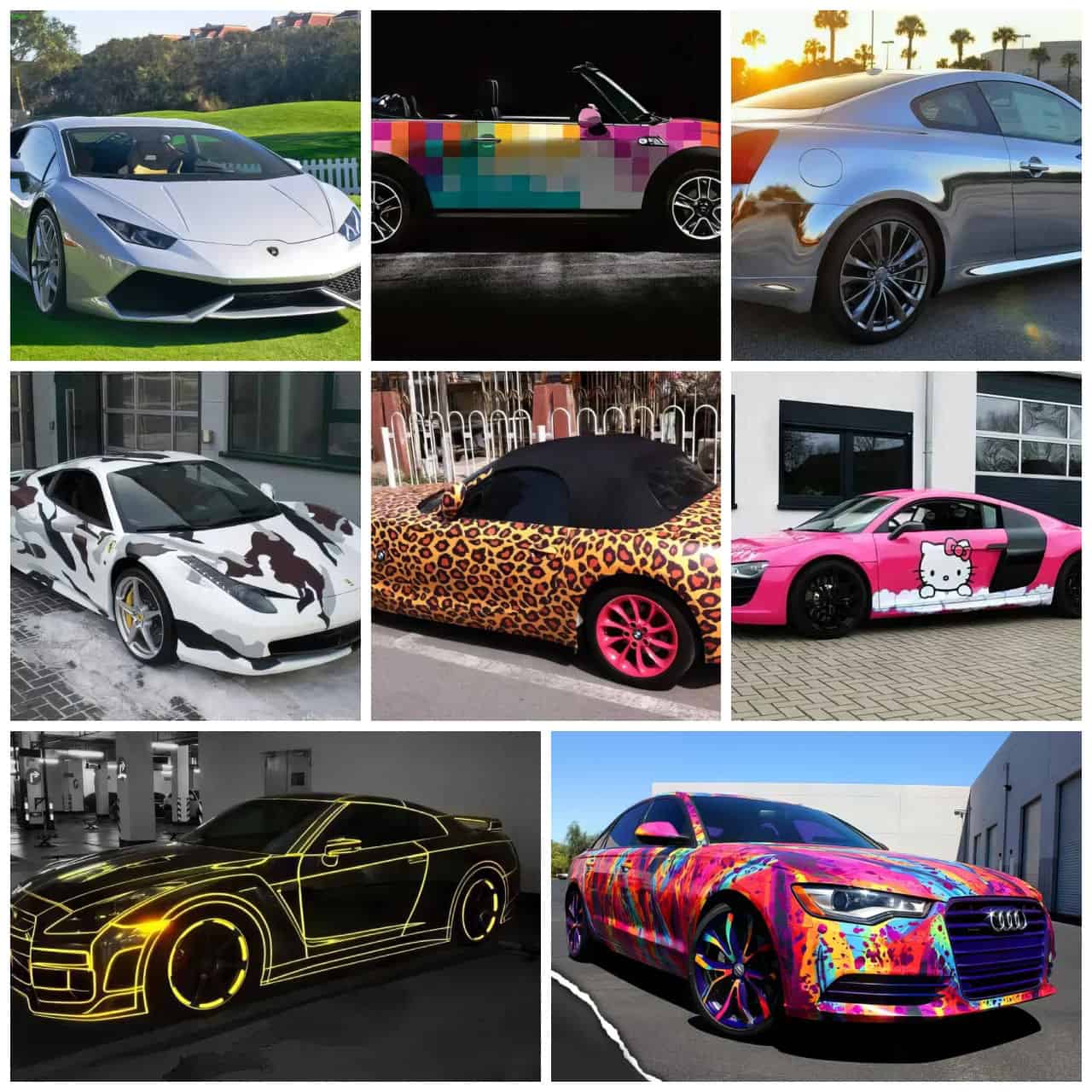

Furthermore, specialized plastic wraps are offered, including metal, matte, and distinctive finishes, which can improve looks while using distinctive characteristics. Understanding these kinds of vinyl covers will enable you to make educated choices based on your job needs, making certain ideal cause both look and long life.

Picking the Right End Up

Choosing the appropriate finish for your vinyl cover is a vital element that can considerably impact the overall aesthetic and performance of your project. Vinyl covers can be found in a range of coatings, each offering distinct visual impacts and efficiency attributes. The most common coatings consist of gloss, matte, satin, and textured options.

A gloss finish offers a high-shine surface that improves color vibrancy and depth, making it excellent for attractive layouts. In comparison, a matte surface supplies a restrained and advanced look, minimizing glow and blemishes.

Satin surfaces strike an equilibrium between matte and gloss, using a soft sheen that includes sophistication without overwhelming the style. Distinctive coatings, such as cleaned metal or carbon fiber, can add an unique responsive element, enhancing the visual allure of your task.

Inevitably, your choice of surface need to line up with the wanted visual and the atmosphere where the wrap will be applied. Think about resilience, upkeep, and the details application to make certain optimal results.

Setup Methods

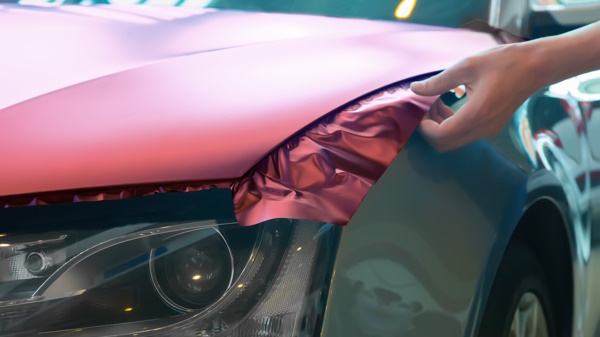

Exactly how can you ensure a flawless application of plastic wraps? The essential hinge on careful prep work and strategy. Begin by cleansing the surface extensively to get rid of grease, wax, and dirt, as any deposit can compromise bond. A clean, smooth surface area is vital for ideal results.

Next, collect necessary tools such as a warmth gun, squeegee, and utility knife. These tools will assist in using the plastic smoothly and trimming excess material. When using the wrap, job in areas, beginning with one side and gently spreading out the plastic while utilizing the squeegee to eliminate air bubbles.

Warm can be beneficial in this process; it makes the plastic extra pliable, permitting it to satisfy contours and shapes quickly. Workout persistence and prevent rushing, as this can result in imbalance or bubbles. In situations of challenging areas, such as around borders or handles, take into consideration using a technique called "tack and stretch" to produce a smooth fit.

Upkeep Tips

To preserve the integrity and look of plastic covers, regular treatment is crucial. Beginning by washing the covered surface area with a gentle soap option and a soft sponge or microfiber cloth. Avoid rough chemicals, as they can harm the vinyl. Tint Pros Vinyl Wraps. It's ideal to clean your cover every two weeks to eliminate dust, gunk, and impurities that can trigger the wrap to shed its radiance.

Dry the surface completely after cleaning, as water spots can end up being long-term if left to completely dry normally. For added protection, take into consideration using a specialized plastic cover sealer, which can aid keep the shade and avoid fading from UV exposure.

Furthermore, stay clear of vehicle parking in straight sunlight for prolonged periods, as extended direct exposure can cause staining and deterioration of the wrap. Ideally, utilize a cars and truck cover or park in shaded areas.

Routinely examine the wrap for any indicators of training or damages. If you observe any kind of concerns, resolve them immediately to stop additional degeneration. Complying with these maintenance pointers will certainly make about his certain that your plastic wrap stays vivid and prolongs its lifespan, ultimately boosting the visual appeals of your project.

Typical Blunders to Avoid

When it comes to plastic wraps, staying clear of typical risks can dramatically impact both the application process and the longevity of the wrap. Correct cleaning and priming are important to make certain that the plastic sticks successfully.

Another typical mistake is picking the incorrect kind of vinyl for the specific application. Various jobs require various products; for example, a lorry cover should utilize cast plastic for longevity, while a momentary indicator may be appropriately served by calendared vinyl.

Inadequate warmth application throughout installation can likewise lead to issues such as creases and improper adherence. Making use of a warm gun at the proper temperature is essential for collaborating with the vinyl, particularly in tough areas like sides or curves.

Lastly, forgeting post-installation treatment can shorten the life-span of the wrap. Failure to adhere to upkeep standards, such as preventing rough chemicals or unpleasant cleansing tools, can result in damages. By staying away from these errors, you can boost the efficiency and aesthetic allure of your plastic cover job.

Final Thought

Finally, choosing the proper vinyl cover necessitates mindful factor to consider of different variables, consisting of the sort of vinyl, coating alternatives, and setup techniques. Proper preparation and adherence to ideal techniques are important for attaining ideal outcomes and making certain the durability of the wrap. By making and avoiding typical mistakes notified choices, individuals can successfully enhance the aesthetic charm and toughness of their tasks through the critical use plastic covers.

Plastic wraps can be extensively classified into 2 main types: cast plastic and calendared vinyl.On the various other hand, calendared plastic is made by a process that involves rolling and extending plastic sheets.Selecting Find Out More the appropriate coating for your plastic wrap is an essential variable that can dramatically impact the total visual and functionality of your project.When it comes visit this site to vinyl covers, staying clear of common challenges can significantly influence both the application procedure and the long life of the cover.In final thought, picking the appropriate vinyl cover necessitates careful consideration of various factors, consisting of the type of vinyl, finish choices, and installation techniques.

Report this page